Makina Odzaza Wafer Packing Line L Mtundu

Kufotokozera Kwachidule:

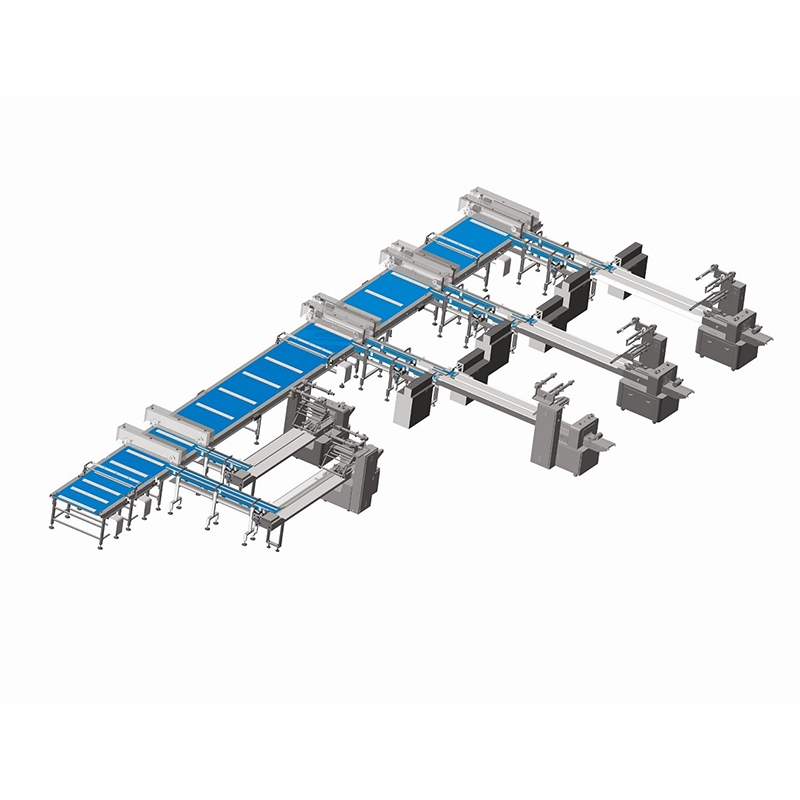

Mzere wolongedza wa wafter wodziwikiratu umagwiritsidwa ntchito pazophatikizira ndi zinthu zina zofananira zokhala ndi mphamvu yayikulu, koma mwadongosolo komanso mawonekedwe okhazikika. Imathetsa mavuto achikhalidwe monga mtunda wapakati pakati pa zinthu, kutembenukira movutikira, kusakhazikika pamizere, ndi zina zambiri kuti mukwaniritse mawonekedwe amodzi kapena angapo.

Tsatanetsatane wa Zamalonda

Zolemba Zamalonda

Tsatanetsatane wa Zamalonda

Makina onyamula okhawa amapangidwira zinthu zomwe zimakhala ndi thireyi kapena bokosi, ndipo mzere wopakirawu ukhoza kunyamula thireyi ndikunyamula popanda kugwiritsa ntchito pamanja.

Wogwira ntchito m'modzi amatha kugwiritsa ntchito mizere iwiri, zomwe zimathandiza kupulumutsa ndalama zogwirira ntchito kwa makasitomala.

Mzere wolowera ndi kulongedza uwu uli ndi deoxidizer kapena deoxidizing agent pad feeder, thireyi yoyamwa pansi, tray automatic loading unit ndi makina olongedza.

Kuthamanga kwapang'onopang'ono kwa tray kukweza ndi kuyika mzere ndi matumba 100-120 pamphindi.

1. Kuyambitsa Zamalonda kwa Zida Zomata Zokhazikika Zokhazikika za Swiss Roll

Dongosolo loyikamo lawafali ndi njira yopangira zinthu zambiri, yomwe imatha kunyamula chophika chimodzi komanso chophatikizika chambiri. Tinapanga dongosolo lonse lolongedza molingana ndi masanjidwe anu ndi kufunsa kwanu. Kuthamanga kwakukulu kumatha kufika matumba 250 / mphindi. Kuthamanga kwa paketi ya banja kumadalira kukula kwake.

2. Ntchito Yaikulu ya Makina Odzaza Chakudya kwa Wafer

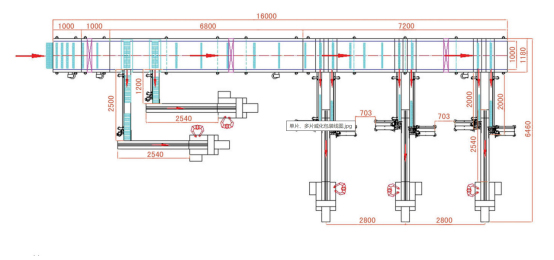

Mzere wolongedza wa wafer uli ndi chowongolera mtunda, chowongolera chobwerera, gawo losankhira magalimoto, ndi makina onyamula. Dongosololi lithandizira kugwirizanitsa ma wafer auto, kutalikirana, kugawa, ndikutumiza kugawo losankhira ndikumaliza kulongedza kuti zisungidwe mosalekeza komanso mwadongosolo ndi zinyalala zochepa komanso phukusi lokongola. Kupopera mowa ndi kulipiritsa mpweya ndizosankha.

Liwiro lolongedza mzere umodzi limatha kufikira matumba a 80-220 / min.

Dongosolo lonse loyikamo limatengera 220V, 50HZ, gawo limodzi. Total Mphamvu ndi 26KW

Dongosolo lakulongedza chakudya litha kugwiritsa ntchito mitundu yosiyanasiyana yonyamula malinga ndi zomwe kasitomala amafunsa.

3. Ubwino wa Automatic Food Packing System ya Wafer Biscuit

Mzere wopingasa wonyamula katundu wokhala ndi chipangizo cholumikizira magalimoto komanso chivundikiro choteteza. Chipangizo chodziwongolera chokha ndichosasankha.

Kapangidwe kake, ntchito yosavuta, kuyeretsa kosavuta, ndi kukonza. Kusintha kosavuta kwazinthu zosiyanasiyana kapena makonda a parameter.

Dongosolo Loyang'anira limagwiritsa ntchito zamagetsi zapamwamba kwambiri, zanzeru PLC, zenera logwira, ndi HMI yabwino, imagwira ntchito mosavuta komanso mosavuta.

Mzere wolongedza wothamanga wokhala ndi lamba wothamanga wosiyanasiyana kuti ukonze mikate kapena makeke kuti utsimikizire kuthamanga kwambiri komanso kupeza molondola.

Makina odzaza chakudya okha ndi makina amagwiritsa ntchito chitsulo chosapanga dzimbiri ndi baffle ya Nylon, yosavuta kugwira ntchito ndi kuyeretsa.

Lamba wa PU amatha kutulutsidwa popanda zida mu mphindi imodzi ndikukhala ndi hopper kuti atenge zinyalala zazinthu, zomwe ndizosavuta kuyeretsa ndi kukonza.

Makina opangira chakudya ndi osavuta, osavuta kugwiritsa ntchito, osavuta kuyeretsa ndi kukonza. Kusintha kosavuta kwazinthu zosiyanasiyana kapena makonda a parameter.

Dongosolo loyang'anira zida zonyamula filimu zapulasitiki zimagwiritsa ntchito zamagetsi zapamwamba kwambiri, zanzeru PLC, zenera logwira, ndi HMI yabwino, imagwira ntchito mosavuta komanso mosavuta.

Tiwonjezera cholumikizira cha 90-degree kapena 180-degree chotembenuza pamakina olongedza molingana ndi masanjidwe a fakitale ya makasitomala kapena malo.

Okonzeka ndi mita chojambulira ndi kulemera checker, amene akhoza basi kugwirizana ndi otaya ma CD dongosolo.

Makina odzaza chakudya a Wafer okhala ndi chipangizo choyanjanitsira okha komanso chipangizo chowongolera chalamba ndichosankha.

Mzere wolongedza ukhoza kugwirizanitsa zowotcha (zogulitsa) ndikuzipereka ku gawo losankhira mwadongosolo kuti zitsimikizire kuthamanga kwambiri ndikuzipeza molondola.

Lamba wa PU wamakina olongedza amatha kutulutsidwa popanda zida ndikukhala ndi hopper kuti atenge zinyalala zazinthu, zosavuta kuyeretsa ndi kukonza.

Kapangidwe kake, ntchito yosavuta, kuyeretsa komanso kukonza bwino. Kusintha kosavuta kwazinthu zosiyanasiyana kapena makonda a parameter.

Dongosolo lowongolera mizere yopyapyala limagwiritsa ntchito zamagetsi zapamwamba kwambiri, zanzeru PLC, zenera logwira, ndi HMI yabwino, imagwira ntchito mosavuta komanso mosavuta.

Lamba wa PU wa mzere wolongedza wa wafer amatha kugwiritsa ntchito umboni womata wamtundu woyera mwa kusankha.

4. Kugwiritsa Ntchito Makina Odzipangira okha

Yogwira kulongedza chakudya extruded ndi zina wamba mankhwala, amene anapanga ndi kudula makina. Zolumikizidwa ndi mzere wakale wopanga ndi automatic feeder kapena manual feeder.

5. Zitsanzo zakuyika

6. Kujambula kwa Automatic Packaging Solution

7. Packaging System Tsatanetsatane.

(1) Wowongolera mtunda

Ntchito yayikulu ya chowongolera mtunda ndikukokera mtunda wa mankhwala kapena kuwasunga m'mizere.

(2) Kugawa ma conveyor

Chotengera ichi chogawira yankho la phukusili chimagwiritsidwa ntchito popereka zinthu m'mizere yophatikizira yosiyanasiyana. Kutalika kwa magawowa kumadalira mphamvu yopangira makasitomala kapena kapangidwe ka fakitale.

(3) Kankhira Direction

Makina owongolera amangogwiritsa ntchito makina opangira ma wafer, omwe amathandizira kusintha komwe akulowera ndikutumiza kumakina osiyanasiyana.

(4) Lamba wosungira

Ntchito yayikulu ya Belt yosungirako ndikusunga zowotchazo ndikuthandizira kubweretsa kumakina onyamula, kumaliza kuyika.

(5) Servo pusher

Chiyambi: servo pusher iyi imangogwiritsa ntchito pamzere wapabanja wa wafer. Kuti mawu, ngati mukufuna 6pcs pa thumba (2layer ndi aliyense wosanjikiza zidutswa 3), ndiye gawo ili liyenera kuyitanitsa. Ngati mungofunika kulongedza chidutswa chimodzi, ndiye kuti palibe chifukwa cha magawo awa.

Ntchito: Ntchito yayikulu ndikukankhira kagulu kakang'ono kamene kamalowa mu conveyor, kenako phukusi.

(6)Chigawo chosankha

Chiyambi cha kusanja kachitidwe ka phukusi:

Magawo osankhidwa amakhala ndi malamba 2 onyamula ndi masensa 5-6.

Ntchito ya unit yosankhidwa:

Ntchito yayikulu ya gawo losankhirali ndikuwongolera liwiro la kudyetsa kwazinthu, kuziyika, ndikuzilumikiza ndi makina onyamula okha. Kamodzi wazindikira mankhwala kwambiri, kudyetsa liwiro m`mbuyo, ngati kusowa mankhwala, ndiye kudyetsa liwiro kulankhula posachedwapa.

Ubwino wa gawo losankhira:

Kuchepetsa ntchito ya anthu ndikuwonetsetsa kuti makina onyamula katundu akuyenda pa liwiro lokhazikika ndi zinyalala zochepa zazinthu.